DIN2391-1/EN 10305-1 BK NBK GBK din2391 precision seamless steel pipe

Product Description

DIN2391-1/EN 10305-1 Precision Seamless Steel Pipe

Detailed Description

din2391 Precision Steel Pipe

Carbon steel tubes for machine structural purposes.

Standard:

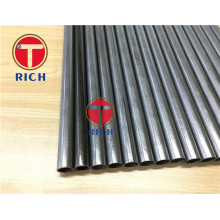

DIN2391-1: Seamless Precision Steel Tube.

EN 10305-1: Steel tubes for precision applications - Technical delivery conditions –

Part 1: Seamless cold drawn tubes.

Size (mm):

Outer Dimensions: 4.0mm ~ 100.0mm

Wall Thickness: 2mm ~ 25 mm

Length: max 12000mm

Application:

Detailed Description

Carbon steel tubes for machine structural purposes.

Standard:

DIN2391-1: Seamless Precision Steel Tube.

EN 10305-1: Steel tubes for precision applications - Technical delivery conditions –

Part 1: Seamless cold drawn tubes.

Size (mm):

Outer Dimensions: 4.0mm ~ 100.0mm

Wall Thickness: 0.5mm ~ 8 mm

Length: max 6000mm

Application: Hydraulic cylinder, construction machinery, pneumatic components, automobile Or motorcycle's parts, concrete pump tubes, motor shell, pipe core for aluminum foil and so on.

Steel grade: DIN2391-1(ST35, ST45, ST52), EN10305-1(E215, E235, E355).

Packing: Bare/bundles/crates/crate protection at the both sides of tubes or as per customers' requirements .

Painting: as requested

Packing: Bare/bundles/crates/crate protection at the both sides of tubes or as per customers' requirements .

Painting: as requested

| Name | Din 2391 prcision carbon steel tube made in china |

| Standard | Din 2391 |

| Material | St35,St45,St52 |

| Supply Condition | Cold drawn seamless steel tube, stress relieved and honed or skived roller burnished |

| Appearance | Tube shall have a smooth internal and external surface consistent with cold working process, tube inner surface should be free from rust, scratches and other surface irregularities. |

| Tolerance on Outer Dia. | ≤ Dia 40 +/-0.2 mm |

| Surface Roughness | Ra = 0.4~0.8 Micron |

| Application | Cold drawn or cold rolled precision seamless steel tubes for hydraulic pressure and pneumatic services.For Auto use,machinery use,oil cylinder tube,motorcycle shock reducer use,auto shock reducer inner cylinder,etc.Seamless Steel Pipes for low and medium pressure boiler, high pressure boiler, ship-building,Liquid service, petroleum cracking, chemical fertilizer equipment,Drawing-oil-equipment and structure purposes. |

| material | Chemical Composition(%) | ||||

| C max. | Si max. | Mn | P max. | S max. | |

| St 35 | 0.17 | 0.35 | ³0.40 | 0.025 | 0.025 |

| St 45 | 0.21 | 0.35 | ³0.40 | 0.025 | 0.025 |

| St 52 | 0.22 | 0.55 | £1.60 | 0.025 | 0.025 |

| material | Cold finished (hard)BK(+C) | Cold finished (Soft)BKW | Cold finished and stress-relieved BKS(+SR) | ||||

| (+LC) | |||||||

| Tensile Strength(σb/MPa) | Elongation(δ5/%) | Tensile Strength(σb/MPa) | Elongation(δ5/%) | Tensile Strength(σb/MPa) | Yield Point(Mpa) | Elongation(δ5/%) | |

| St 35 | 480 | 6 | 420 | 10 | 420 | 315 | 14 |

| St 45 | 580 | 5 | 520 | 8 | 520 | 375 | 12 |

| St 52 | 640 | 4 | 580 | ||||

| material | Annealed GBK(+A) | Normalized NBK(+N) | |||

| Tensile Strength(σb/MPa) | Elongation(δ5/%) | Tensile Strength(σb/MPa) | Yield Point(Mpa) | Elongation(δ5/%) | |

| St 35 | 315 | 25 | 340-470 | 235 | 25 |

| St 45 | 390 | 21 | 440-570 | 255 | 21 |

| St 52 | 490 | 22 | |||

| material | Annealed GBK(+A) | Normalized NBK(+N) | |||

| Tensile Strength(σb/MPa) | Elongation(δ5/%) | Tensile Strength(σb/MPa) | Yield Point(Mpa) | Elongation(δ5/%) | |

| St 35 | 315 | 25 | 340-470 | 235 | 25 |

| St 45 | 390 | 21 | 440-570 | 255 | 21 |

| St 52 | 490 | 22 | |||

| Designation | Symbol | Description |

| Cold finished (hard) | BK(+C) | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation |

| Cold finished (Soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding) |

| Cold finished and stress-relieved | BKS(+SR) | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK(+A) | The last Cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK(+N) | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

| SIZE | SIZE |

| OD*thickness | OD*thickness |

| 25*2-3-4-5-6 | 54*5-6-8-10-12 |

| 27*2-3-4-5-6 | 55*5-6-8-10-12 |

| 28*2-3-4-5-6 | 57*5-6-8-10-12 |

| 30*3-4-5-6-8-10 | 60*5-6-8-10-12 |

| 32*3-4-5-6-8-10 | 63.5*5-6-8-10-12-14 |

| 34*3-4-5-6-8-10 | 65*5-6-8-10-12-14 |

| 36*3-4-5-6-8-10 | 68*5-6-8-10-12-14 |

| 37*3-4-5-6-8-10 | 70*5-6-8-10-12-14 |

| 38*3-4-5-6-8-10 | 73*5-6-8-10-12-14 |

| 40*3-4-5-6-8-10-12 | 76*5-6-8-10-12-14-16 |

| 42*3-4-5-6-8-10-12 | 78*5-6-8-10-12-14-16 |

| 45*3-4-5-6-8-10-12 | 80*5-6-8-10-12-14-16 |

| 46*3-4-5-6-8-10-12 | 83*5-6-8-10-12-14-16 |

| 48*3-4-5-6-8-10-12 | 89*8-10-12-14-16 |

| 50*3-4-5-6-8-10-12 | 95*8-10-12-14-16 |

| 51*5-6-8-10-12 | 98*8-10-12-14-16 |

| 53*5-6-8-10-12 | 100*8-10-12-14-16 |

Contact us if you need more details on Precision Seamless Steel Pipe. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Precision Carbon Steel Pipes、Din2391 Precision Pipe. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Precision Steel Pipe

Premium Related Products